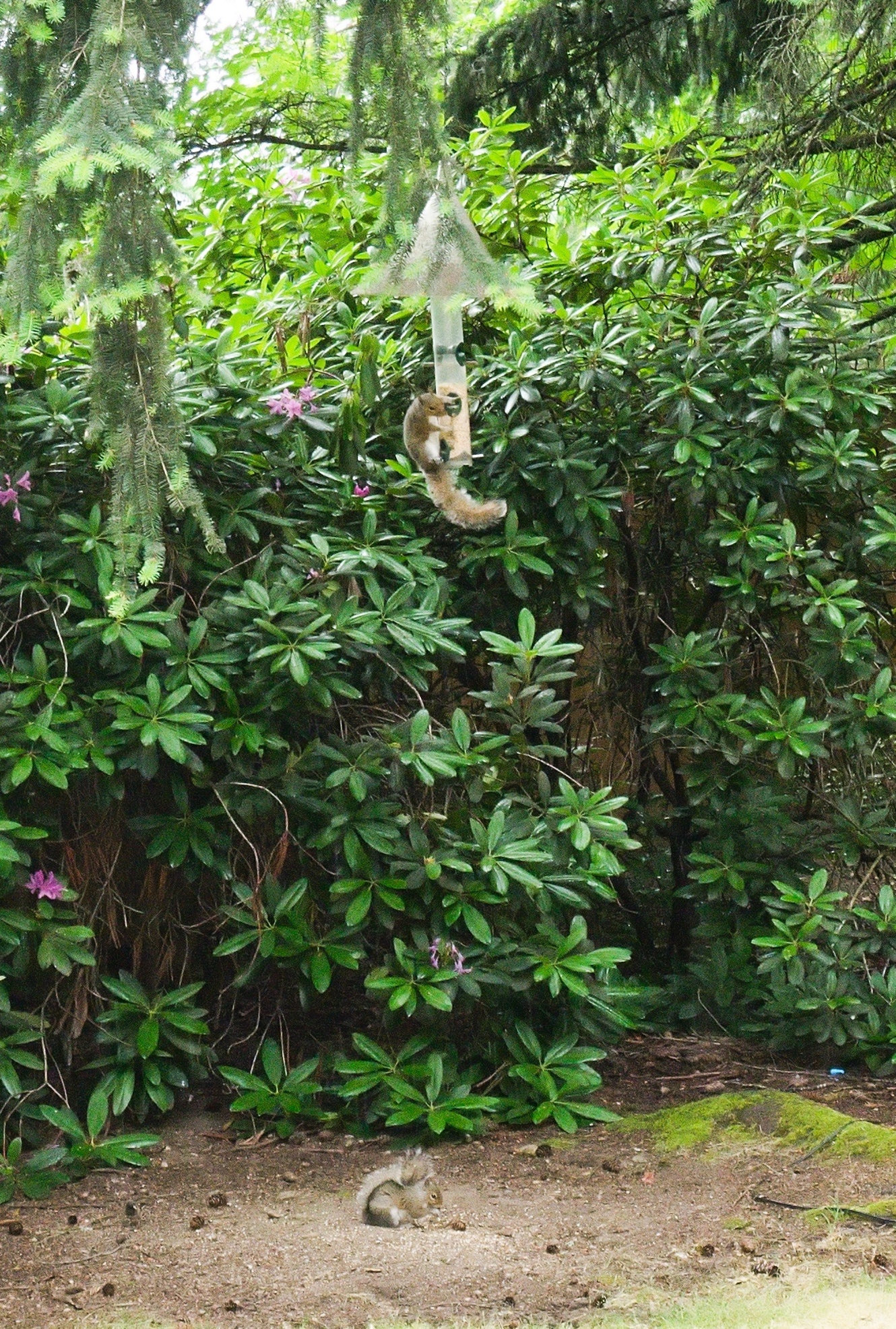

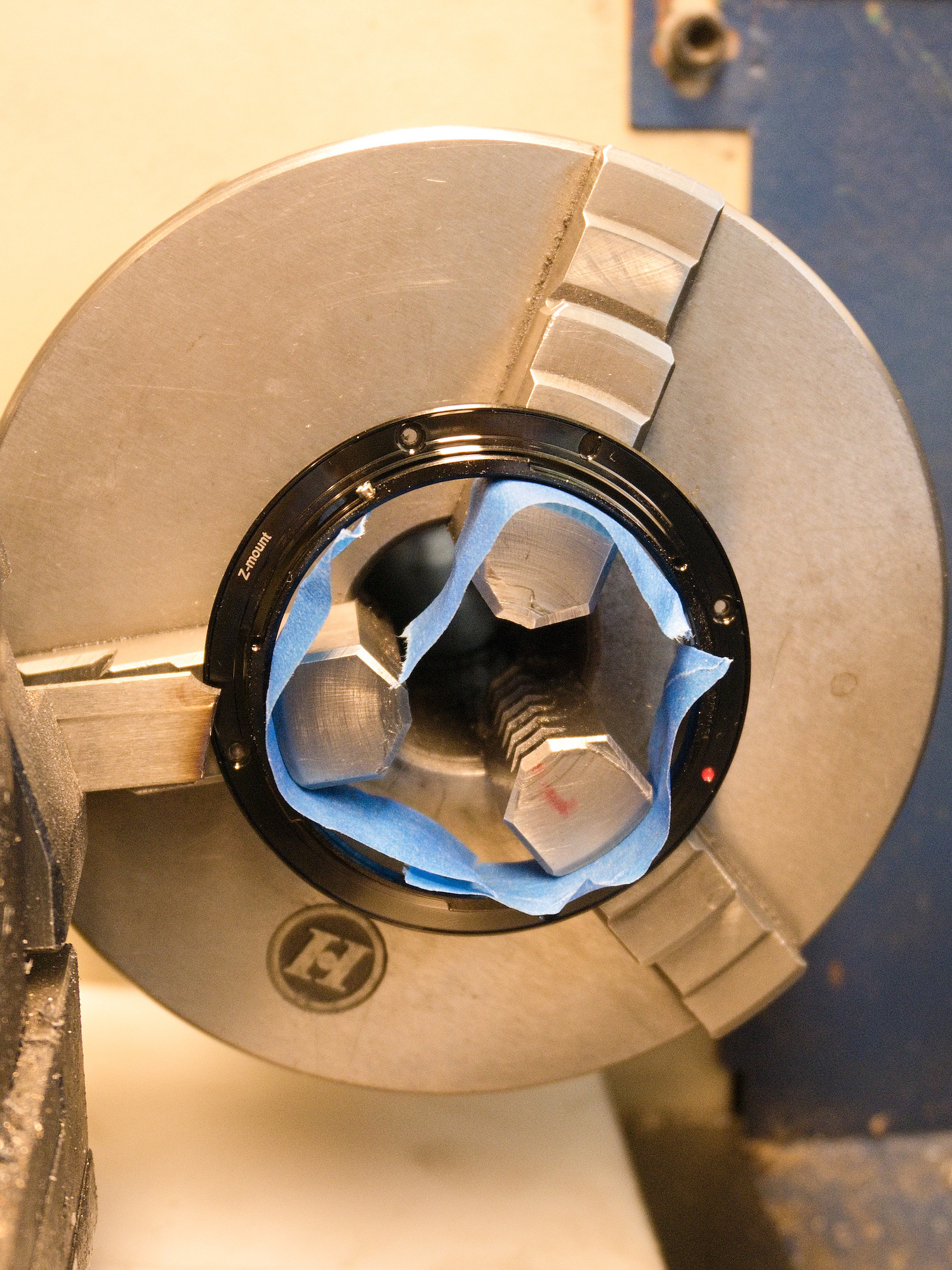

The support ring of the 7Artisans Fisheye for Nikon Z mount is 55.04mm, while the Nikon Z mount itself is 55mm.

Tight fit. You can barely screw that thing on.

The Nikkor 16-50mm is 54.91mm.

Even a cheap F to Z mount adapter is within tolerances.

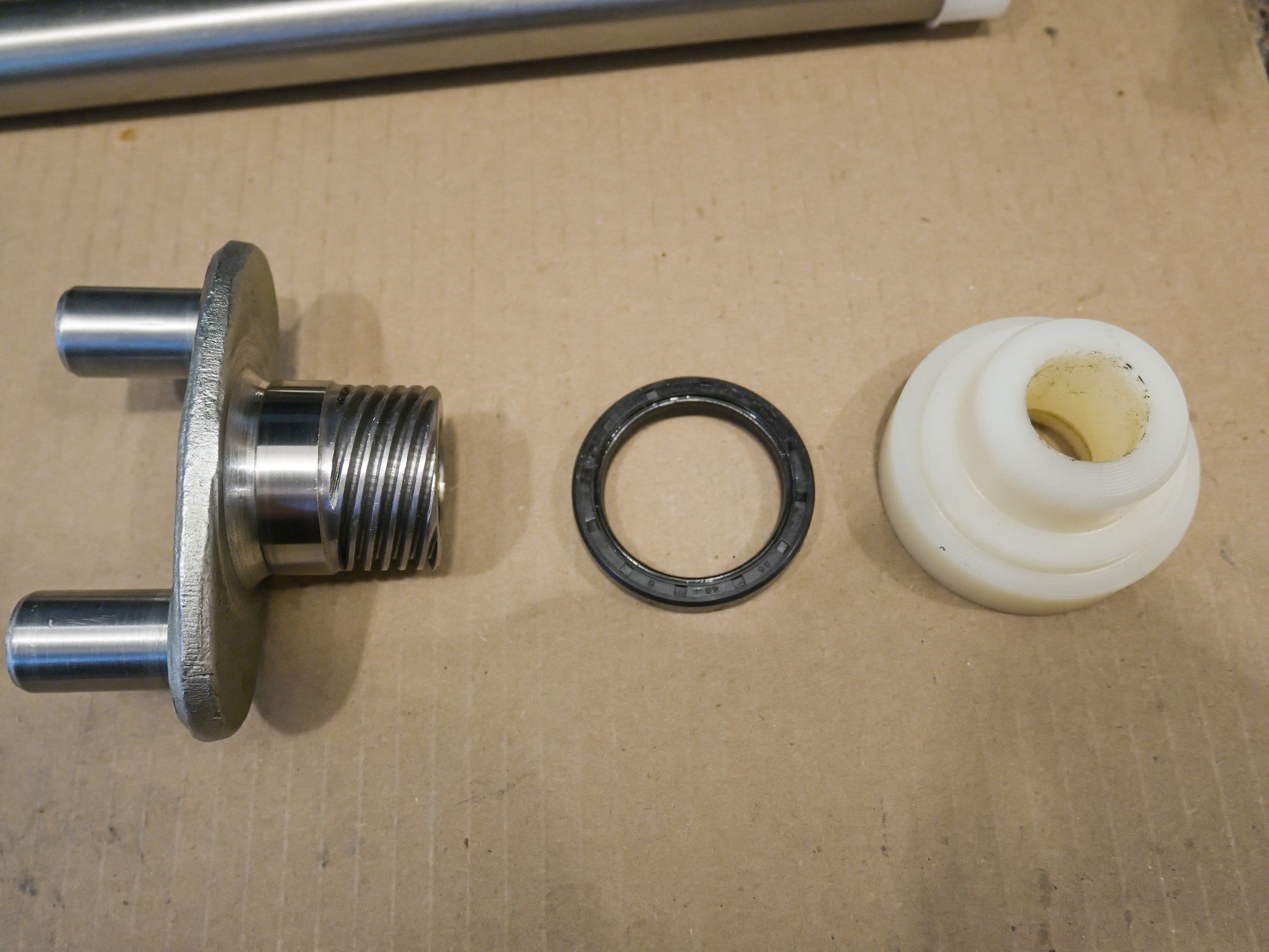

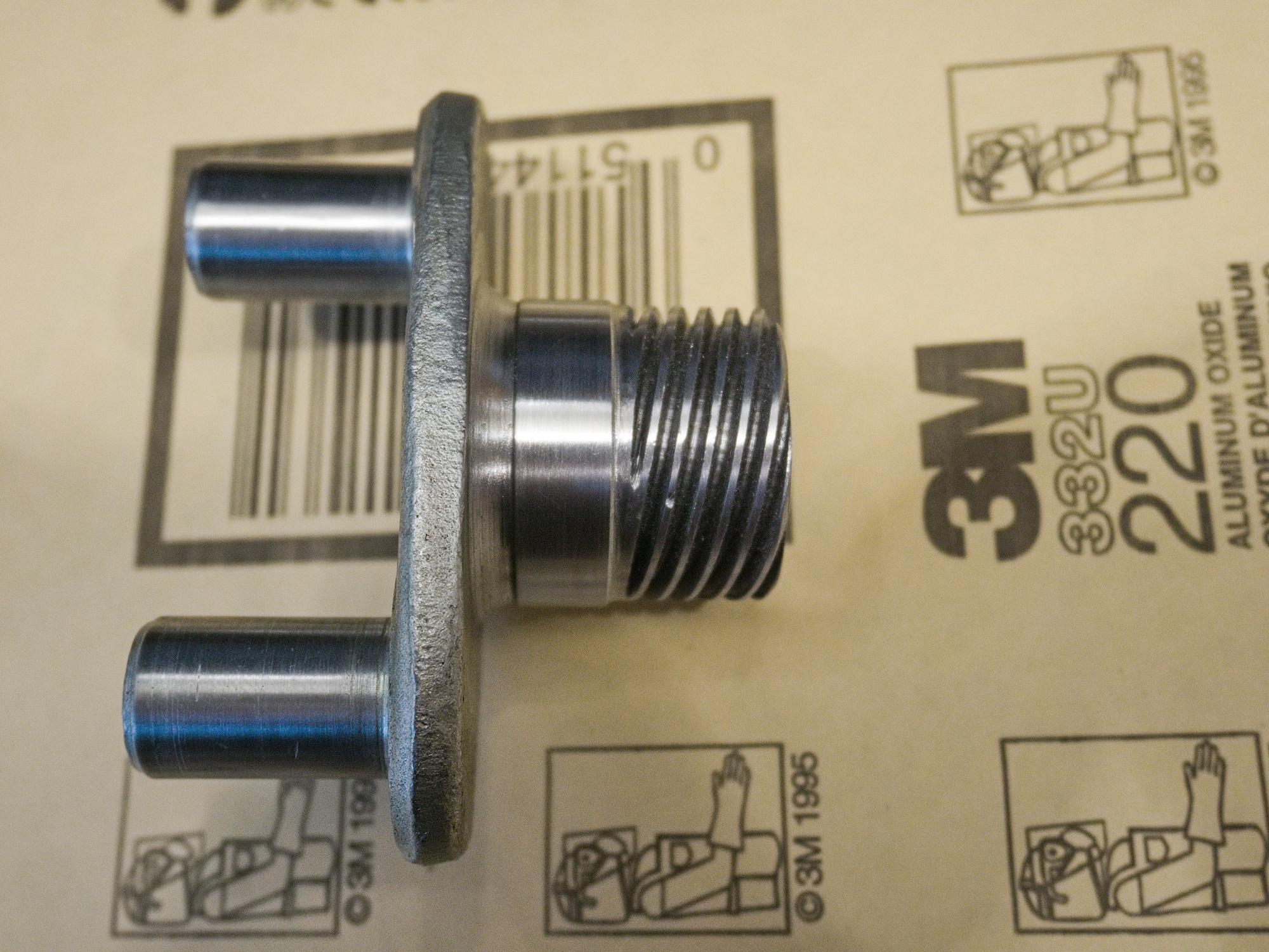

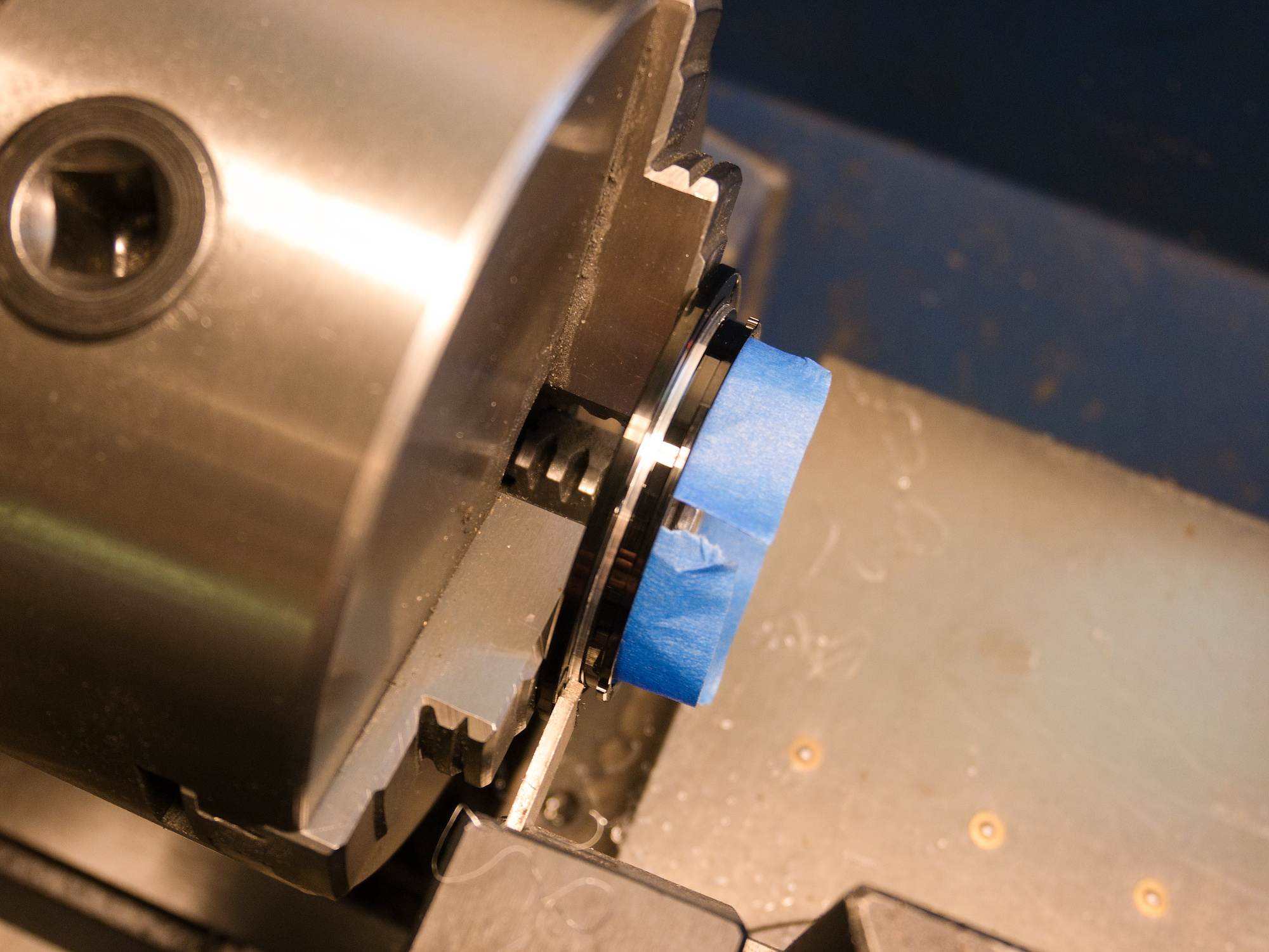

To fix this, first unscrew the lens mount.

The support ring needed to be reduced to 54.60mm. The mount is not perfectly round and a first trial to 54.80mm was still too tight.

Chinese tolerances of the overall mount, I guess.

If you don't have access to a Lathe, you can use a fine file and make several rounds to take off the 0.2mm. Take your time and use tape to protect the ring.

Note: The mount is positioned with the red dot next to the Aperture print.

Done, Lens meets Camera.

Now it fits mirrorless.

Update:

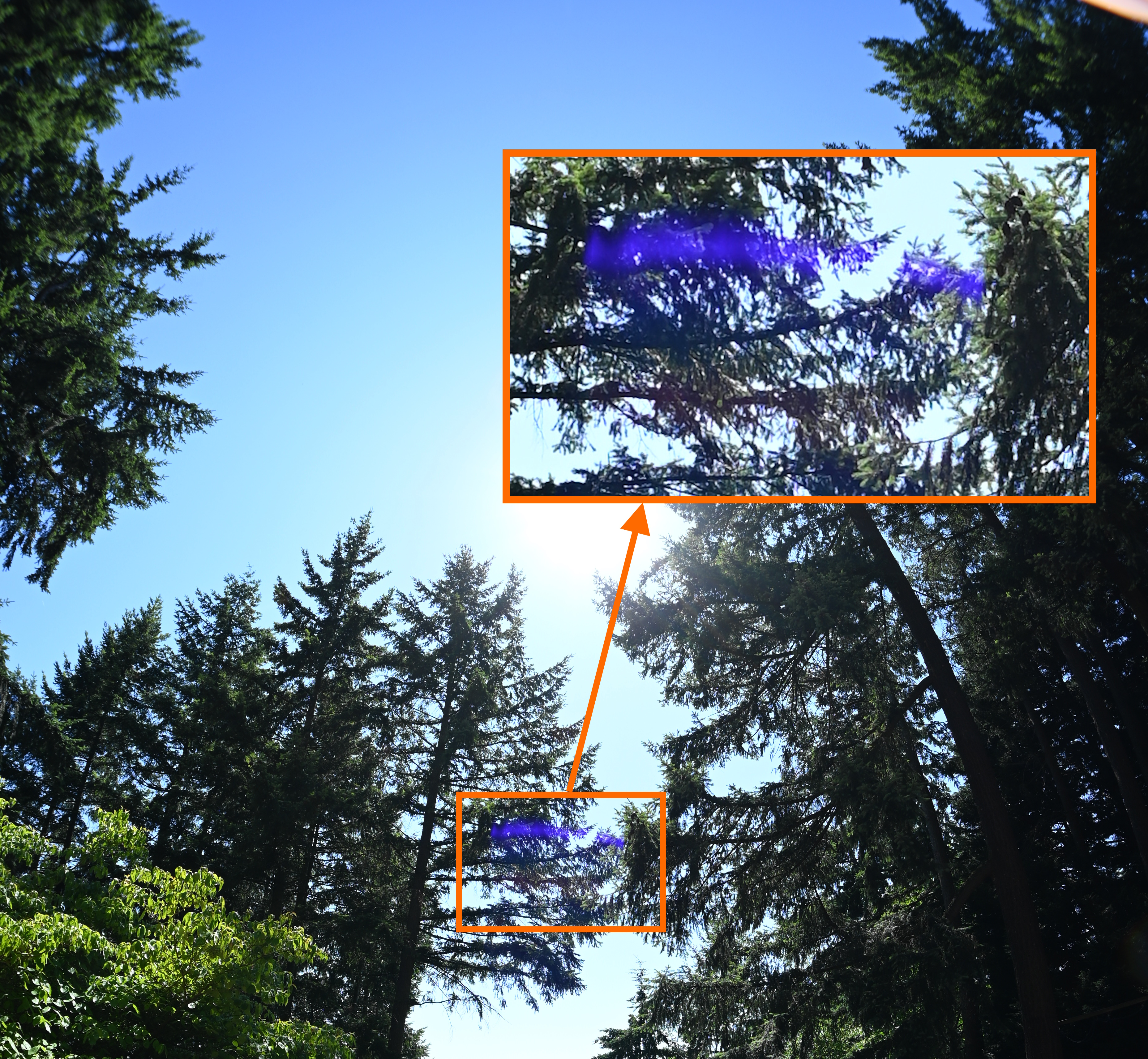

The lens is sharp only on one side.

Crop from the top part of the test picture. This is with f/5.6:

Camera rotated 180°:

Stopping down to f/8 improves things and of course its getting better with f/16.

Pay for a f/2.8 lens and use it like a pinhole camera.

Another creative feature is the remarkable colored lens flare when you point towards the sun with f/8-f/16. You get that for free when doing a 360x180° panoramic image on a sunny day.

Update of the Update:

I have contacted 7artisans (both the main site and the store), but I have not received any response.

I have solved the problem by switching to a TTArtisan 7.5mm f/2.0. It matches the sharpness of my copy of the 7artisans already at f/2.0.

The diameter of the support ring is 54.90mm and mounts smoothly.

They even fixed the spelling error of the name on the lens in the latest production run.

This concludes my business with 7artisans.